Breif introduction

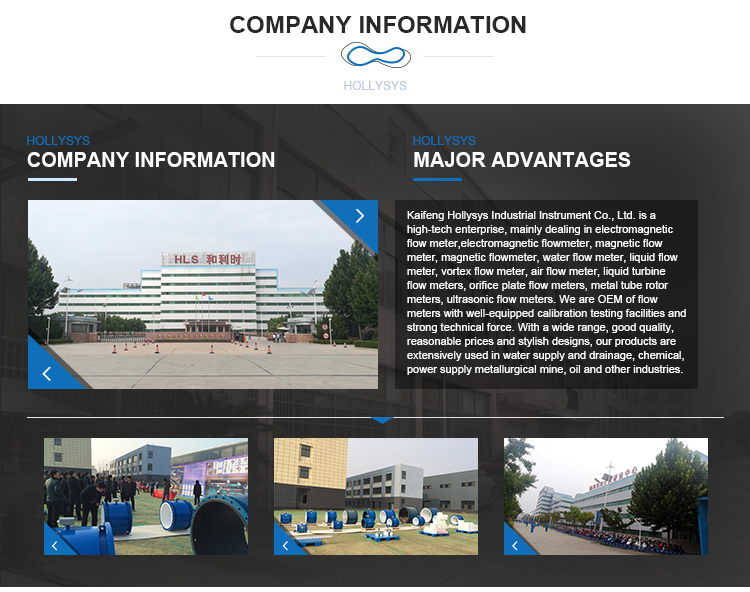

Hollysys Series magnetic flow meter is intended for fluid metering in most industries including water, waste?water, food and beverage, pharmaceutical and chemical.

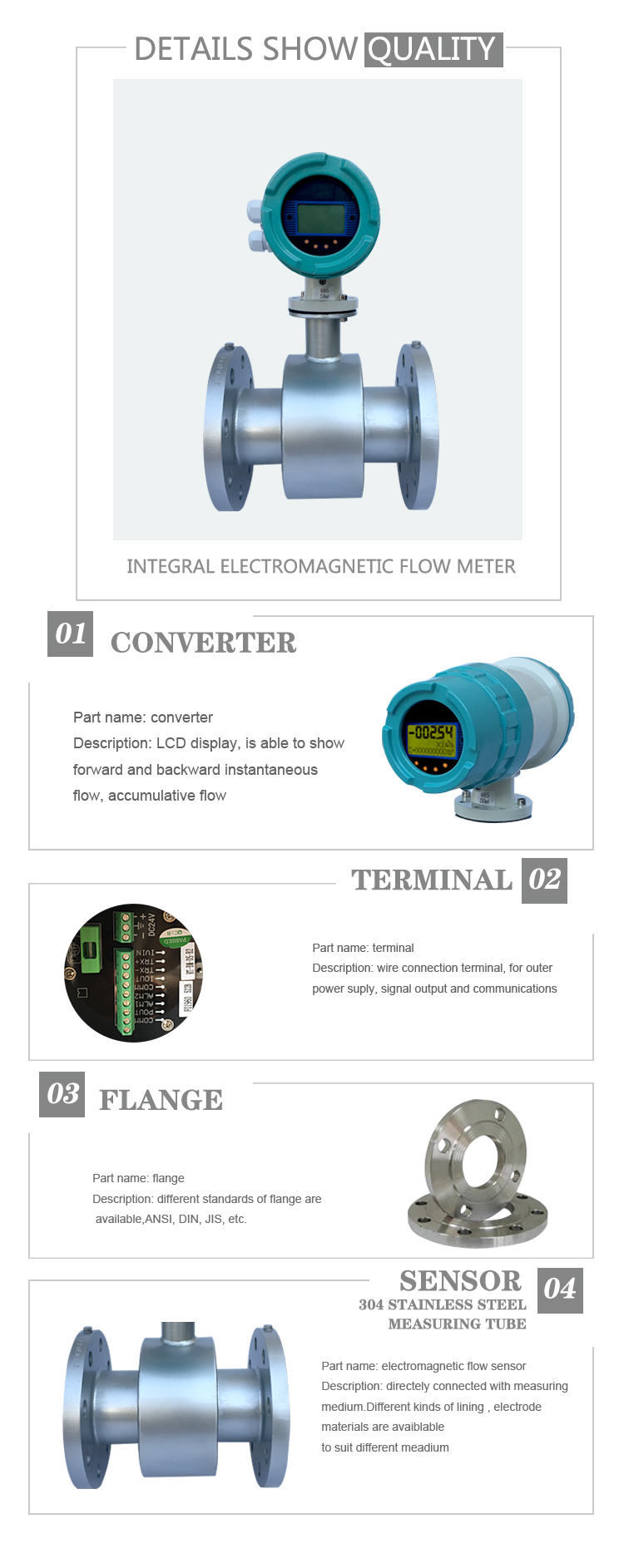

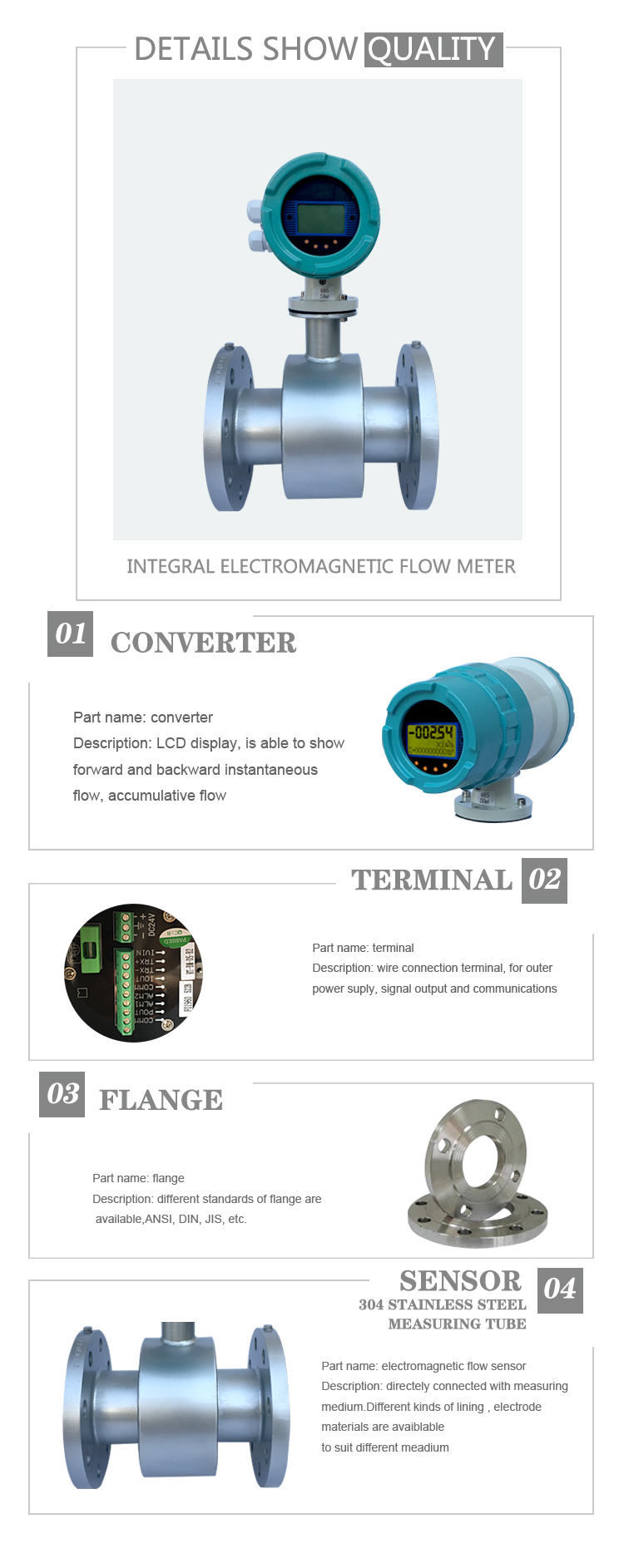

The basic components of an electromagnetic flow meter are: ?

The sensor/ detector, which includes the flow tube, isolating liner and measuring electrodes

The converter/ transmitter, which is the electronic device responsible for the signal processing, flow calculation, display and output signals.

Each meter is factory tested and calibrated.?A calibration certificate is included with each meter.

Main Features

1). With simple structure ,the flow meter is of high reliability.

2). The wide range of the nominal bore is suitable for all the pipe size between DN8?and DN3000.

3). Different material are available, carton steel, SS304, SS316.

4). Different flange standard are optional, DIN, JIS, ANSI, EN, etc.

5). Measurement is independent of fluid density,?viscosity,?humidity,?temperature,?pressure.

6). The sensor with advanced processing technology and liquid airproof is of long natural life and of nice resistance to shaking leakage.?It guarantees the instrument good precision and stability.

How to select right liner material?

Lining Material |

Main Performance |

Applicable Range |

|

Polytetrafl

uoroethylene (PTFE / Teflon)

|

1. It is the plastic with most stable chemical properties, and is resistant to boiled hydrochloric acid, sulphuric acid, nitric acid and aqua regia, and also strong alkali and varied organic solvents.

2. Wear resistant performance is lower than polyurethane rubber.

3. Negative pressure resistance is lower than poly neoprene.

|

1.Strong corrosive medium such as concentrated acid and alkali.

2.Sanitary medium. |

Fluorinated Ethylene Propylene (F46) |

Chemical performance is similar as PTFE, the negative pressure resistance is better than PTFE, the price is relatively high. |

Additional Mesh PFA |

Chemical performance is similar as PTFE, good negative pressure resistance, the price is high. |

Water, sewage, weak wearable mud ore pulp. |

Poly Neoprene |

1. With very good elasticity, high breaking tenacity, good wear resistant performance.

2. Resistant to common low concentration acid and alkali and salt, not resistant to oxidizing medium. |

Polyurethane Rubber |

1. Extremely strong wear resistant performance.

2. The corrosion resistant performance is relatively low. |

Neutral and strong wearable ore pulp, coal pulp and mud.? |

How to select right electrode material?

Electrode material |

Applications |

Stainless steel SUS316 |

Applicable in water,sewage and corrosive mediums. |

Widely used in industries of petrol,chemistry,carbamide,etc |

|

Stainless steel covered

with tungsten carbide

|

Applicable in mediums of no corrosive and low abrasion. |

Hastelloy B(HB) |

Having strong resistance to hydrochloric acid of any consistance which

is below bioling piont. |

Also resistable against vitriol,phosphate, |

hydrofluoricacid,organic acid etc which are oxidable acid,alkali and?

non-oxidable salt. |

Hastelloy C(HC) |

Be resistant to oxidable acid such as nitric acid,mixed acid |

as well as oxidable salt such as Fe+++,Cu++aStnd sea water |

Titanium |

Applicable in seawater,and kinds of chloride,hypochlorite salt,oxidable

acid (including fuming nitric acid),organic acid,alkali etc. |

Not resistant to a pure reducing acid(such as sulphuric acid,hydrochloric?

acid corrosion. |

But if acid contains antioxidant is greatly reduce corrosion. |

Tantalum |

Having strong resistance to corrosive mediums that is similar with glass |

Almost is applicable to all chemical mediums. |

Except for hydrofluoric acid,oleum and alkali. |

Platinum-iridium |

Almost be applicable in all chemical mediums except for ammonium salt. |