Do you know the correct installation method of common flowmeter?

The flowmeter is an instrument that indicates the measured flow and / or the total amount of fluid in the selected time interval. It is also an essential instrument for measuring liquid and gas flow. You must have seen many different types of flowmeters at ordinary times. The correct installation method is very important for the flowmeter. Let's learn about the installation points of eight types of common flow meters through the following small series.

History of flow?meter

The development of flow measurement can be traced back to ancient water conservancy projects and urban water supply systems. In Caesar's time in ancient Rome, orifice plates have been used to measure the amount of drinking water of residents. Around 1000 BC, ancient Egypt measured the flow of the Nile River by weir method. China's famous Dujiangyan water conservancy project applies the water level observation of baopingkou, water volume and so on. Torricelli laid the theoretical foundation of differential pressure flowmeter in the 17th century, which is a milestone in flow measurement. Since then, the rudiments of many types of flow measurement instruments in the 18th and 19th centuries began to take shape, such as weir, tracer method, pitot tube, venturi tube, volume, turbine and target flowmeter. The rapid development of new generation of flow meters and metering technology in the 20th century has promoted the rapid development of new generation of urban flow meters. So far, it is said that hundreds of flow meters have been put into the market, and many thorny problems in field use are expected to be solved. The work of modern flow measurement technology in China is relatively late, and the flow instruments needed in the early stage were imported from abroad.

01. Electromagnetic flowmeter

The measurement principle of electromagnetic flowmeter does not depend on the characteristics of flow. If there is a certain turbulence and vortex in the pipeline in the non measurement area, it has nothing to do with the measurement.

Key points of installation

A. There shall be no large vibration source at the installation site, and reinforcement measures shall be taken to stabilize the pipeline near the instrument;

B. It cannot be installed near large transformers, motors, pumps and other equipment that produce large magnetic field to avoid interference by electromagnetic field;

C. When the sensor is connected with the pipeline, it shall ensure the full pipe operation, and it is best to install it vertically;

D. The grounding of the transmitter shell can be connected with the nearest grounding grid; The shielded cable (split type) shall be connected according to the instructions, and the signal cable (to the system) shall be grounded at the single end of the shielding layer system; The short-circuit ring connected between the measuring sensor and the pipeline needs to be grounded, and the grounding resistance should be less than 10 ohms, which cannot be shared with electrical grounding;

E. There should also be a certain straight pipe section upstream of the flowmeter sensor, generally 5D ~ 10D.

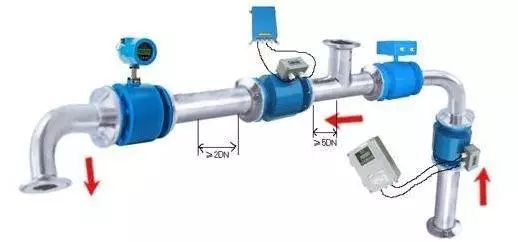

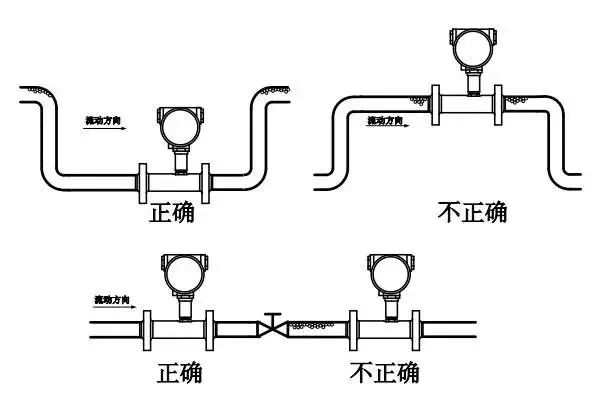

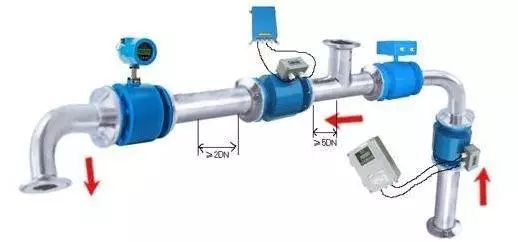

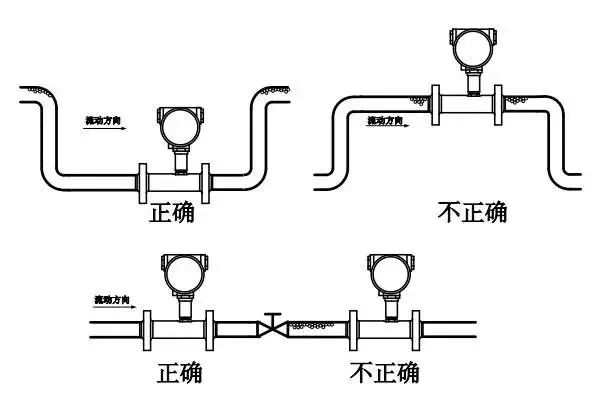

Installation details are as follows:

If there is steady-state eddy current in the measurement area, it will affect the stability and accuracy of the measurement. At this time, the length of the front and rear straight pipe sections can be increased, a flow stabilizer can be used, or the section of the measurement point can be reduced to stabilize the velocity distribution.

The flowmeter can be installed horizontally and vertically, but it should be ensured to avoid the influence of sediment and bubbles on the measuring electrode, and it is better to keep the electrode horizontal axially. When installed vertically, the fluid shall flow from bottom to top.

The sensor cannot be installed at the highest position of the pipeline, which is easy to accumulate bubbles.

Ensure that when the flow sensor is measuring, the pipeline is filled with the measured fluid and there can be no non full pipe state.

If the pipeline is not full or the outlet is vented, the sensor shall be installed on a siphon.

The requirements for the conventional straight pipe section of electromagnetic flowmeter are the first 10d and the last 5D. There are different requirements when there are elbows and valves.

Reasons for grounding of electromagnetic flowmeter:

The measuring electrode in the electromagnetic flowmeter is in a DC or AC electric field. If its environment cannot be effectively shielded under a non-interference condition, it will seriously interfere with the measurement.

If the flowmeter is not grounded, the measurement accuracy of the current must be directly related to the shielding and grounding of the sensor, otherwise the measurement accuracy of the current will be very reliable.

Benefits of electromagnetic flowmeter grounding:

If the pipeline connecting the flowmeter is insulated (relative to the measured medium), the grounding ring shall be used, and its material shall be selected according to the corrosivity of the measured medium.

If it is a Teflon lined measuring sensor, the grounding ring shall be selected in order to ensure the normal operation of the measuring sensor.

02. Ultrasonic flowmeter

Ultrasonic flowmeter is also a common flowmeter. Its installation is the most simple and convenient in the installation of all flowmeters. As long as you select a suitable measuring point, input the pipeline parameters at the measuring point into the flowmeter, and then fix the probe on the pipeline.

Key points of installation

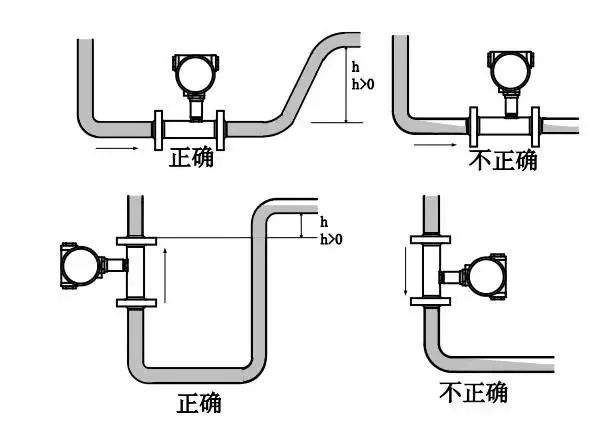

1. Select the pipe section filled with fluid with uniform and dense material and easy for ultrasonic transmission, such as vertical pipe section or horizontal pipe section.

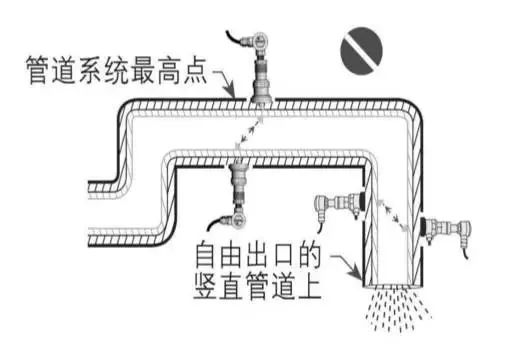

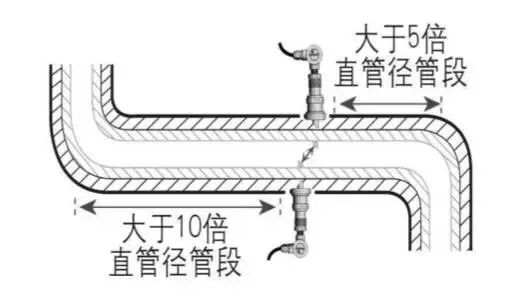

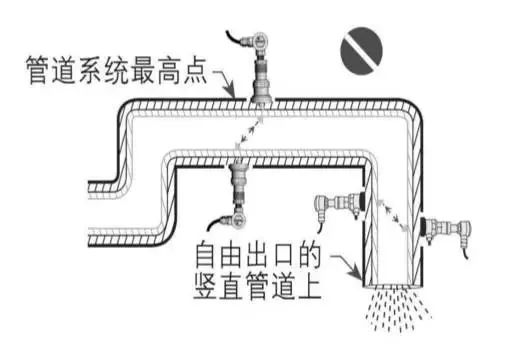

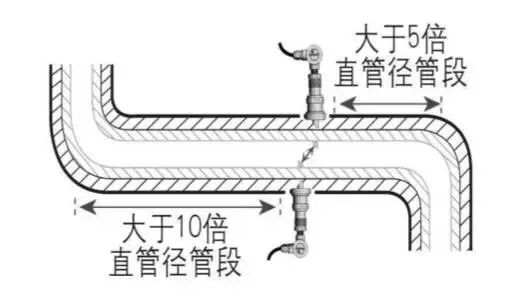

2. The installation distance shall select the straight pipe section with no valve, elbow, reducer and other uniform within 10 times of the straight pipe diameter upstream and 5 times of the straight pipe diameter downstream. The installation point shall be fully away from the interference sources such as valves, pumps, high-voltage electricity and frequency converters.

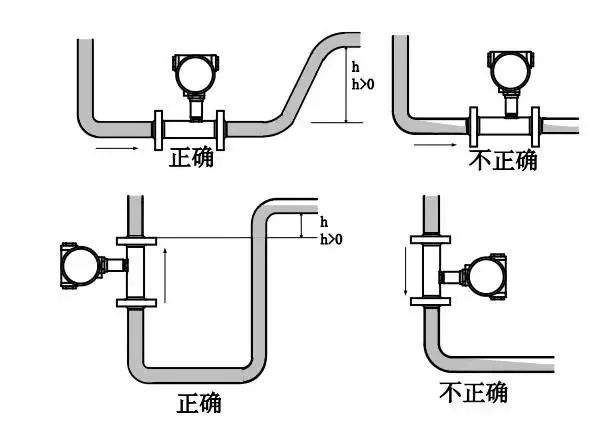

3. Avoid installation at the highest point of the piping system or on vertical pipes with free outlets.

4. For open or half full pipes, the flowmeter shall be installed at the U-shaped pipe section.

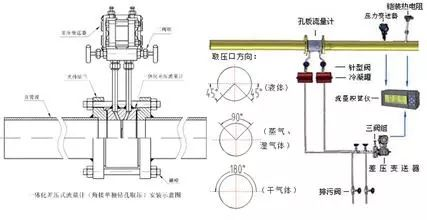

03. Vortex flowmeter

The main installation requirements of vortex flowmeter are the requirements for straight pipe section and pipeline vibration. There shall be long straight pipe sections on the upstream and downstream sides of vortex flow sensor; The pipeline shall not have vibration. If there is vibration, fixed devices shall be added on both sides of the flowmeter.

Key points of installation

For vortex flowmeter, when measuring gas flow, if the measured gas contains a small amount of liquid, the flowmeter shall be installed at a higher place of the pipeline.

When measuring liquid, if the measured liquid contains a small amount of gas, the flowmeter shall be installed at the lower part of the pipeline.

Pressure and temperature taps:

When pressure measurement is required, the pressure tap must be set at 2 ~ 7d downstream of the flowmeter. When temperature measurement is required, set the temperature sensor between 1 ~ 2D downstream of the pressure measuring point.

Pipe support:

Try to install the flowmeter where the vibration acceleration is less than 20m / S2. When the pipeline vibration is too strong, the pipeline shall be installed with reinforcement support.

Sealing gasket:

Never protrude the sealing gasket into the pipe, otherwise it will lead to unacceptable error.

04. Turbine flowmeter

Key points of installation

The turbine flowmeter can be installed horizontally and vertically. When installed vertically, the fluid direction must be upward. The liquid shall fill the pipeline without bubbles.

During installation, the liquid flow direction shall be consistent with the direction of the arrow indicating the flow direction on the sensor housing. During installation, the fluid in the pipeline must be filled to ensure accurate measurement.

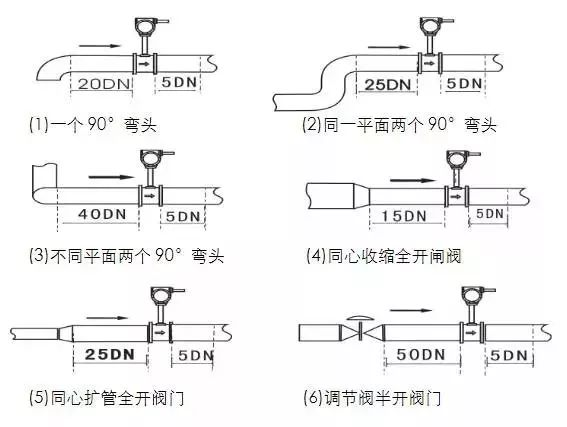

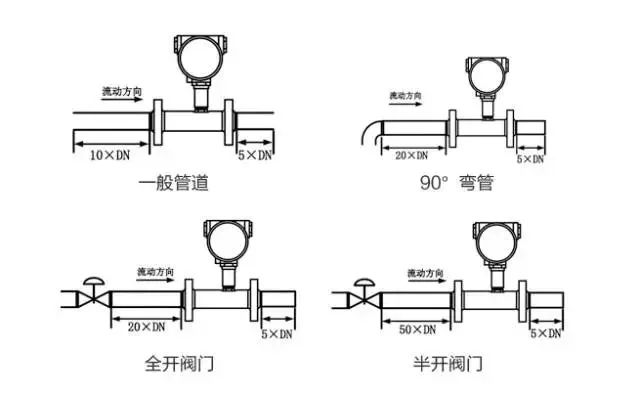

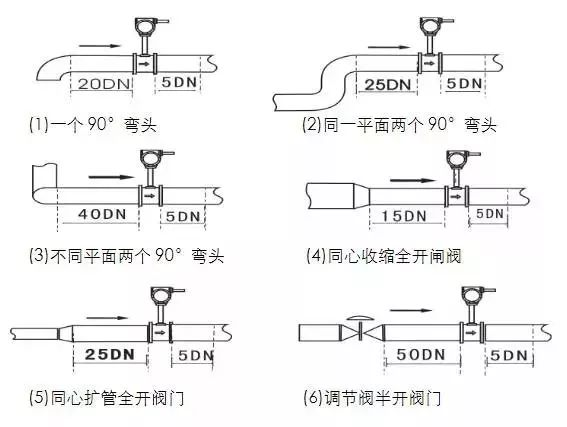

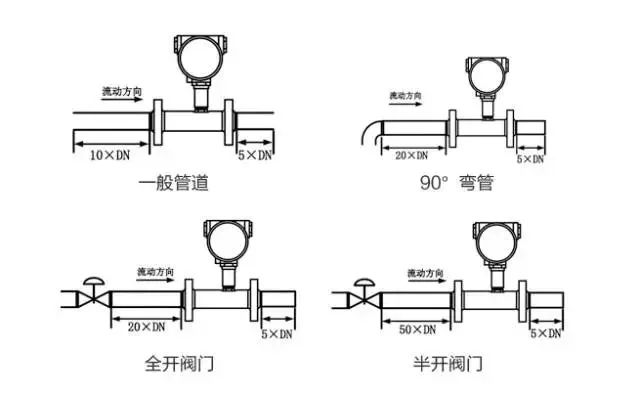

The upstream end of the flowmeter shall have a straight pipe section with a length of at least 10 times the nominal diameter, and the downstream end shall have a straight pipe section with a length of at least 5 times the nominal diameter. Its inner wall shall be smooth and clean without dents, scale, peeling and other defects.

The pipeline axis of the sensor shall be aligned with the axis of the adjacent pipeline, and the gasket for connection and sealing shall not go deep into the inner cavity of the pipeline. The requirements of straight pipe section under different conditions are shown in the figure below.

At the same time, bubbles in the pipeline shall be avoided during installation, otherwise the measurement accuracy will be affected.

05. Veris bar flowmeter

Veris bar flow sensor is a flow sensor designed according to the differential pressure working principle and plug-in installation method.

Structural features: scientific transverse shape, unique anti blocking design, rough treatment of sensor surface and anti silting groove.

Key points of installation

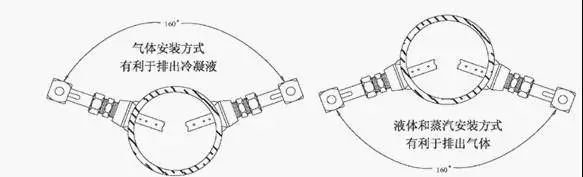

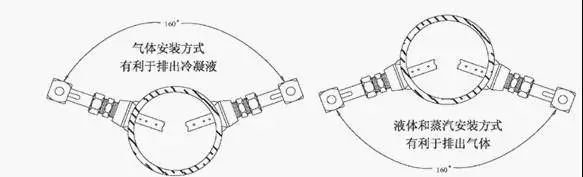

Basic installation method of horizontal pipeline

For horizontal pipeline, it is recommended to install it within 160 degrees above the pipeline when measuring gas, especially for gas with a large amount of water powder, we only recommend this installation;

When measuring liquid, it is recommended to install it within 160 degrees below the pipeline, especially for liquid containing a large amount of gas, we only recommend this installation;

However, it should be noted that for those liquids that are easily gasified, such as liquid olefin media, the insertion direction is the same as that of the gas, which is above the pipeline.

When measuring steam, it is only recommended that the sensor be installed within 160 degrees below the pipe, and the sensor should be at the highest point of the whole measuring device.

Basic installation method of vertical pipeline

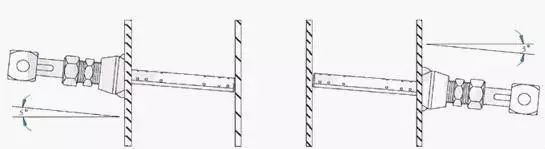

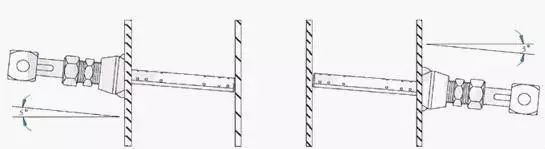

For vertical pipes, it can theoretically be installed within 360 degrees. For wet gas containing a lot of moisture, it is recommended that the sensor be installed with an upward inclination of 5 degrees, as shown in the left figure.

For liquids containing a large amount of gas, it is recommended that the sensor be installed with a downward inclination of 5 degrees, as shown in the right figure. For steam, it is recommended that the sensor be installed with a downward inclination of 5 degrees, as shown in the right figure, and the sensor should be at the highest point in the whole measurement system.

Straight pipe section required for installation

Minimum straight pipe section requirements - 2D installation after bending is shown in the figure.

When the straight pipe sections at the upstream and downstream of the pipeline are not long enough, we recommend installing veybar at twice the inner diameter of the pipeline after the elbow. Due to the complex fluid profile after the elbow, the fluid coefficient K needs to be adjusted appropriately. After adjusting the K-factor, the measurement accuracy is ± 3%, and the repetition accuracy is ± 0.3%

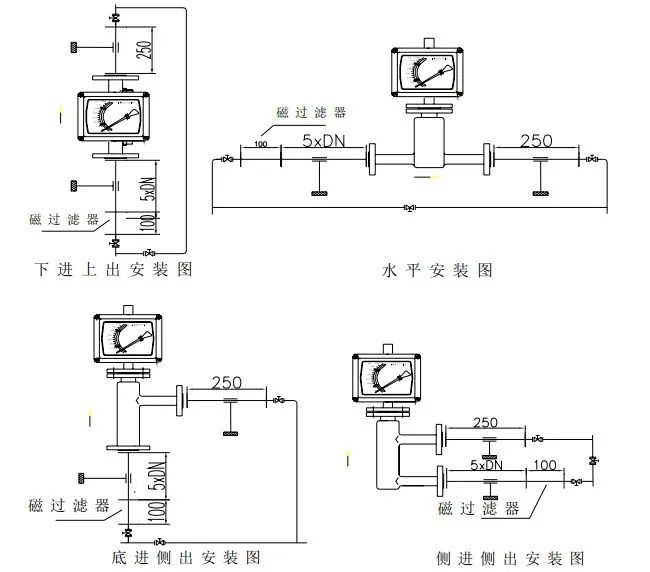

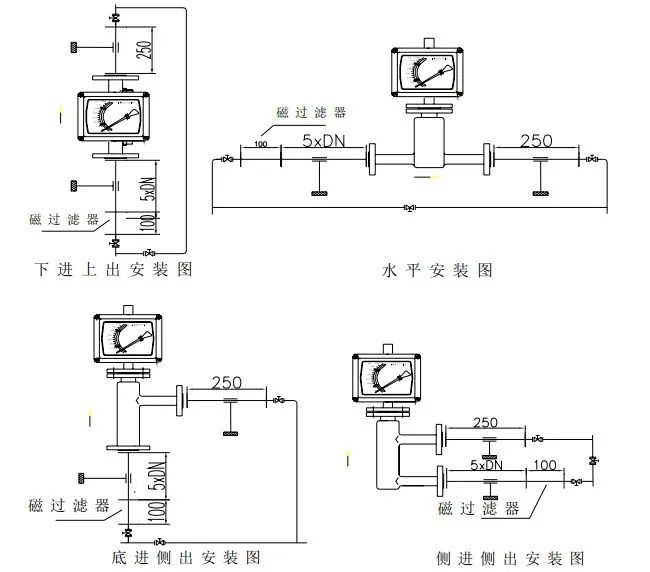

06. Rotameter

Key points of installation

1. Instrument installation direction

Most rotameters must be installed vertically on vibration free pipes without obvious inclination, and the fluid flows through the instrument from bottom to top. The included angle between the center line of the rotameter and the plumb line is generally not more than 5 degrees, and the instrument is of high precision (above level 1.5) θ ≤20°����。 If θ= 12 ° will produce an additional error of 1%. There are no strict requirements for the length of upstream straight pipe section of the instrument, but there are also those with the length of (2-5) d required by the manufacturer, which is not necessary in fact.

2. For installation of dirty fluid

A filter shall be installed upstream of the instrument. When the metal tube rotameter with magnetic coupling is used for the fluid that may contain magnetic impurities, a magnetic filter shall be installed in front of the instrument. Keep the float and cone tube clean, especially for small-diameter instruments. The cleanliness of the float obviously affects the measured value.

3. Installation of expanded range of Rotameter

If the flow range required for measurement is wide, when the range exceeds 10, two floats with different shapes and weights can be placed in one instrument. When the flow is small, take the light float reading, and take the heavy float reading after the float reaches the top. The range can be expanded to 50-100.

4. Installation of pulsating flow of Rotameter

For the pulsation of the flow itself, if there is a reciprocating pump or regulating valve upstream of the proposed instrument position, or there is a large load change downstream, the measurement position shall be changed or the pipeline system shall be remedied and improved, such as adding a buffer tank; If the instrument oscillates, such as the gas pressure is too low during measurement, the upstream valve of the instrument is not fully opened, and the regulating valve is not installed downstream of the instrument, targeted improvement shall be made to overcome it, or the instrument with damping device shall be selected.

5. The rotameter shall exhaust the gas in the instrument for liquid use

For angular metal rotameter whose inlet and outlet are not in a straight line, when used for liquid, pay attention to whether there is residual air in the extended casing of external float displacement, which must be exhausted; If the liquid contains tiny bubbles, it is easy to accumulate in the casing when flowing, and it should be vented regularly. This is more important for small diameter instruments, otherwise the flow indication will be obviously affected.

6. The flow value of rotameter shall be subject to necessary conversion

If the instrument is not specially customized from the rotameter manufacturer according to the use density, viscosity and other medium parameters, the liquid instrument is usually calibrated with water, and the gas instrument is calibrated with air, and the fixed value is in the engineering standard state. When the fluid density, gas pressure and temperature under service conditions are inconsistent with the calibration, necessary conversion shall be made. The conversion formula and method are detailed in the manufacturer's instruction manual of rotameter.

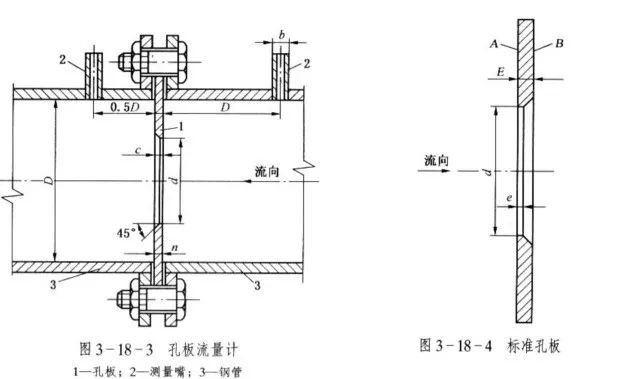

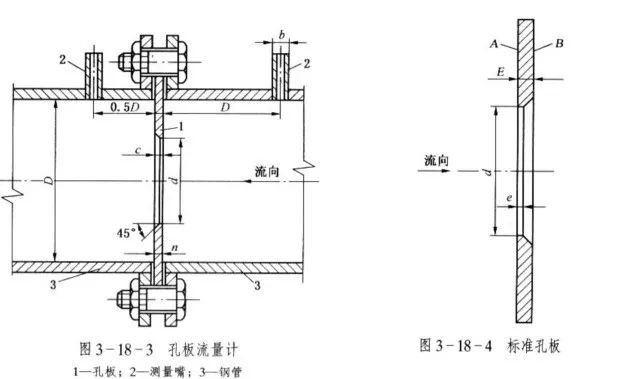

07. Orifice flowmeter

Installation requirements

1. Before the installation of orifice plate, check whether the number and size of throttling device meet the requirements of pipeline installation position.

2. For newly installed pipeline system, the orifice plate must be installed after pipeline flushing and cleaning.

3. Note that the "+" sign in the installation direction of the orifice plate should face the flow beam.

4. The center of the orifice plate shall coincide with the center line of the pipe, and the concentricity error shall not exceed 0.015 (1)/ β - 1) Value of.

5. When the orifice plate is installed in the pipeline, its end face shall be vertical to the pipeline axis, and the Perpendicularity Error shall not exceed ± 1 °.

6. The sealing gasket used for clamping the orifice plate (including between the ring chamber and the flange, between the ring chamber and the orifice plate) shall not protrude into the inner wall of the pipeline after clamping.

7. The installation position of orifice plate must be tight and no leakage is allowed. Therefore, the installation must be carried out before the pipeline pressure test.

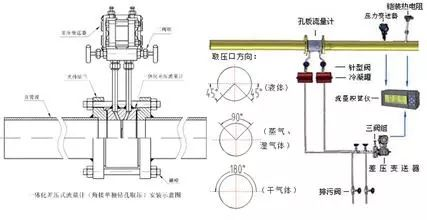

8. The impulse pipe shall be laid vertically or obliquely, and its inclination shall not be less than 1:12. For fluids with higher viscosity, the inclination should also be increased. When the transmission distance of differential pressure signal is greater than 3m, the impulse pipe shall be inclined in sections, and gas collectors and precipitators shall be installed at each high point and low point respectively.

9. In order to avoid the distortion of differential pressure signal transmission, the positive and negative impulse pipes should be laid as close as possible, and anti freezing measures should be taken in severe cold areas. Electric heating or steam insulation can be adopted, but the false differential pressure caused by overheating and vaporization of the measured medium and gas generation in the impulse pipe shall be prevented.

10. When the orifice is installed on the vertical main pipe, the position of the pressure tap can be arbitrarily selected on the plane of the pressure tap. The orifice plate is installed in the horizontal or inclined main pipeline, and the position of the pressure tap is shown in Figure 4.

11. The impulse pipe shall be made of pressure resistant and corrosion-resistant materials according to the properties of the measured medium. Its inner diameter shall not be less than 6mm and its length shall be within 16m.

08. Mass flowmeter

Installation requirements

1. The installation position shall be selected to avoid electromagnetic interference. The installation position and cable laying of sensors and transmitters shall be far away from the equipment prone to strong electromagnetic field, such as high-power motors, transformer facilities, frequency conversion equipment, etc.

2. The mass flow sensor shall be installed so that the flow direction identification of the sensor is consistent with the flow direction of the fluid. And make the arrow point in the same direction as the flow configured inside the transmitter. (Note: the mass flowmeter can be used in both directions. If the installation direction is opposite to the actual flow direction, modify the flow direction configuration in the transmitter.)

3. The mass flowmeter is a flow instrument measured according to the vibration principle of the measuring pipe. Therefore, when installing the sensor, it should be considered to make a solid support near the flange of the process pipeline on both sides (about 2 ~ 10 times the pipe diameter) to avoid vibration of the instrument and related pipelines. If strong pipeline vibration is inevitable, it is recommended to isolate the pipeline system from the instrument sensor with flexible pipe.

4. Because the mass flowmeter works according to the Coriolis force principle, in order to avoid the influence of gravity on the measurement accuracy. Whether the measuring pipe of mass flowmeter is installed upward or downward, try to keep the measuring pipe vertical or horizontal with the ground plane.

5. During installation, the connecting flange faces shall be parallel to each other, and the centers of the two flanges shall be located on the same axis to avoid additional stress. It is strictly forbidden to straighten the upstream and downstream process pipes with the sensor, otherwise the measurement will be affected or even the sensor will be damaged.

6. On the upstream and downstream pipelines of the sensor, it is recommended to install stop valves and bypass valves to facilitate zero adjustment, daily maintenance and ensure that the sensor can also be in a full pipe state when it is not working. The mass flowmeter used in the trade handover site does not need to add bypass